Process Automation for Engineers

Synera leverages Low-Code to automate engineering processes, fostering agile hardware development while seamlessly connecting CAx tools and centralizing expertise across the organization.

Our software is trusted by engineers at

Power to the engineers

Synera is an automation platform specifically designed for engineers. It allows to build complex automations 10x faster. Thanks to the user-friendly UI and shareable templates anyone from your team can easily use and modify them to level up their work – without programming skills.

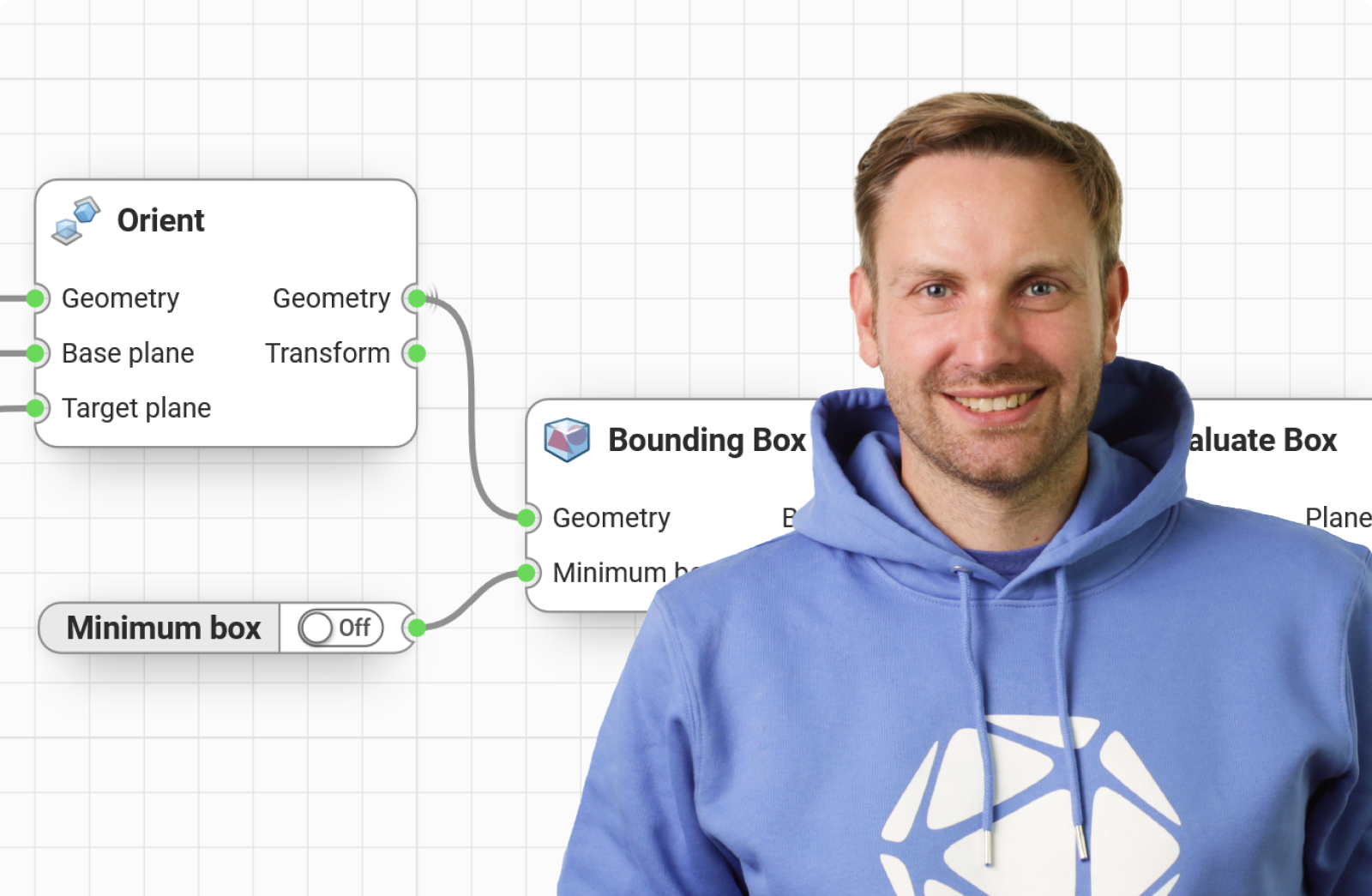

Move fast with nodes, customize with code

Automate your workflows with more than 1.700 pre-built nodes that handle the bulk of your work. If you need custom logic, simply build your own nodes or add a few lines of Python code – directly in Synera.

Powerful integrations to connect to anything

Synera provides robust integrations for all major CAD systems, CAE software, PLM systems, Excel, and Matlab that work out-of-the-box. Additionally, you can connect to any SaaS platform with a REST API.

Joyful and interactive automation experience

Immediately get the results of your workflow at each step and iterate faster – no compile and run cycle required. The integrated viewer let’s you see the what you build without switching between tools.

The engineering software you’ll enjoy using

Synera is an intuitive platform that makes automating repetitive tasks quick, easy, and even enjoyable.

Learn more about the productSee what else you can automate with Synera

Design Automation

Design for Sustainability

Design for Sustainability

Report Generation

Topology Reconstruction

Extend capabilities, boost productivity, and share knowledge through Connected Engineering

Overcome the limits of one size fits all none tools

Break free from rigid tools that box you in and get more out of your existing engineering software. With Synera, you can extend the capabilities of the software you already use or build custom workflows from scratch that you can’t buy off the shelf. This gives you the flexibility to automate your work exactly as you need.

Remove bottlenecks to meet your deadlines

Don't waste time with manual iteration loops and repetitive tasks. Engineers need to be able to develop new products at lightning speed. With Synera, you can automate repetitive tasks and speed up iteration loops. Meet your ambitious deadlines in a fraction of the time without working long hours.

Put an end to your knowledge gap

Developing groundbreaking products requires expert knowledge at each step. But finding, hiring, and retaining simulation and automation experts is a constant struggle. With Synera, you can make the knowledge of your experts accessible to anyone, multiplying the expertise in your company.

The platform behind fast-paced engineering teams

Discover our technical whitepapers

Get in-depth generative design knowledge covering a spectrum of subjects ranging from the advantages of AI, Automotive, to specialized EV topics or cost engineering.